Outstanding dispersing agent for oligomers

Nanotechnology

- "nanos" is the Greek word for "dwarf"

- Nanotechnology is the technology for manufacturing and using functional structures in the range of nanometers , between 1 and 100nm

- OLISTOP OGD is mineral based, modified nano lamellas of a diameter of approximatly 10-20nm

Properties

- Very high dispersing capacity for oligomers

- Easily dispersible in cold water

No influence on the colour depth of nuance - No influence on the fastnesses

No changes necessary regarding the dyeing process or the dyestuff application - Part of "Rapid Dyeing Process" for dyeing Polester fibres

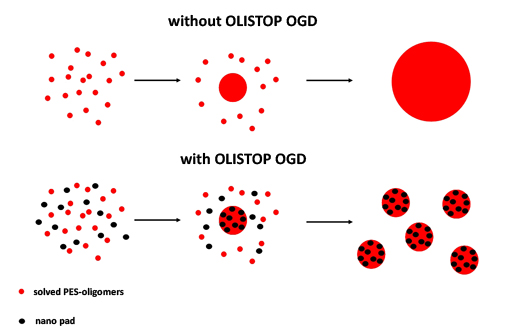

How Olistop OGD works

- Oligomers possess the property to be discharged from the polyester fibre at higher temperatures ans assemble to form large agglomerates.

- OLISTOP OGD prevents oligomers from forming and obviates the growth of oligomer agglomerates and crystals by binding itself on the oligomers before their agglomeration:

- thus the oligomers will be dispersed so finely that they will not disturb in the following processes anymore.

Evidence of the effectiveness of Olistop OGD

To check the effciency of OLISTOP OGD a liquor inoculated with oligomers is treated with an addition of the oligomer dispersant at 130°C for 60 minutes. It is then filterd off through a black filter paper with a water jet vacuum.

- The whiter the filter the coarser the oligomers which have been deposited, that means the worse the dispersing properties.

Microscopic analysis

Dyeing from practice 200x magnification with the KEYENCE digital microscope VHX 600:

Application of OLISTOP OGD

Dye bath:

OLISTOP OGD must be put firstly in the dye bath.

Here besides the usally applied chemicals and auxiliaries, amounts of 1.0 - 3.0 g/l are recommended.

Reductive clearing:

To boost the effect it is possible to apply OLISTOP OGD also in the reductive clearing. 1.0

Here amounts of 1.0- 2.0 g/l are recommended.

NOTE:

In a practice trial it is especially important that the dyeing apparatus has been thoroughly boiled out before the trial.For this the following recipe is recommended:

- 3.0-4.0 g/l Tecoclean FTK

- 8.0-15 ml/l NaOH 38°Bé

- 1.0-2.0 g/l Tecoredukt TH or SRM 235%

- purify for 30 - 60 Min. at 130°C

- drain hot

- rinse well

Depending on the degree of impurity the cleaning process may have to be carried out for a second time.